History of the enterprise

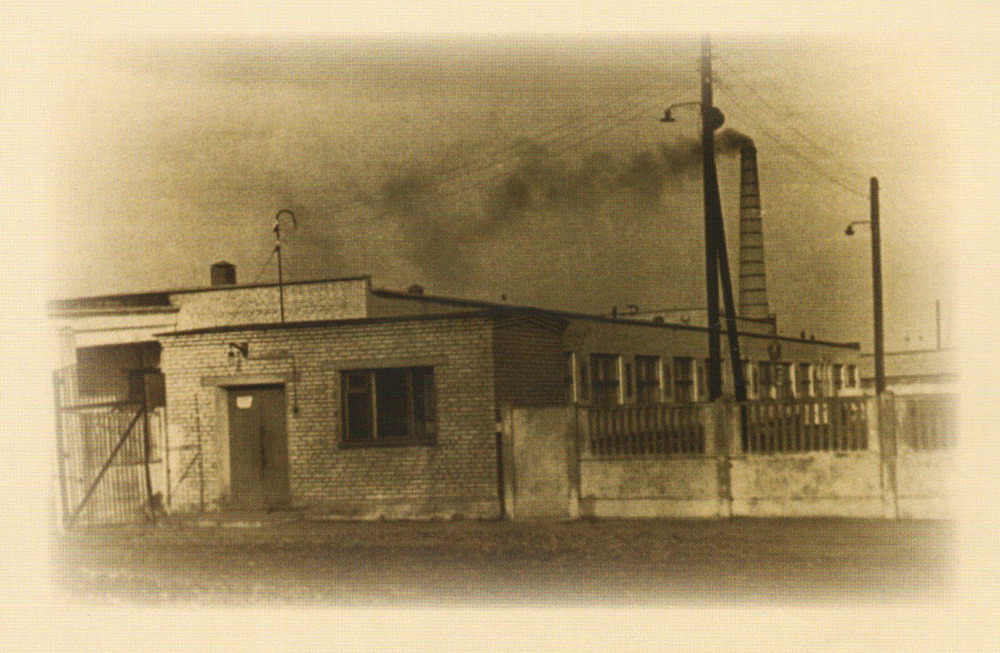

The history of the factory started in 1947

It was located on a small square in the center of the city. At the time, it was fitted with primitive equipment and produced a limited range of products (butter, milk, sour cream).

Mostly manual labor was used for production of dairy products

People stocked up firewood and ice. All cooling operations were performed with ice; cheese heads were huge, 14 kg each. Wooden boxes were closed with the help of rivets and nails. Load handling operations were performed manually. Milk was delivered in flasks, which were also loaded manually.

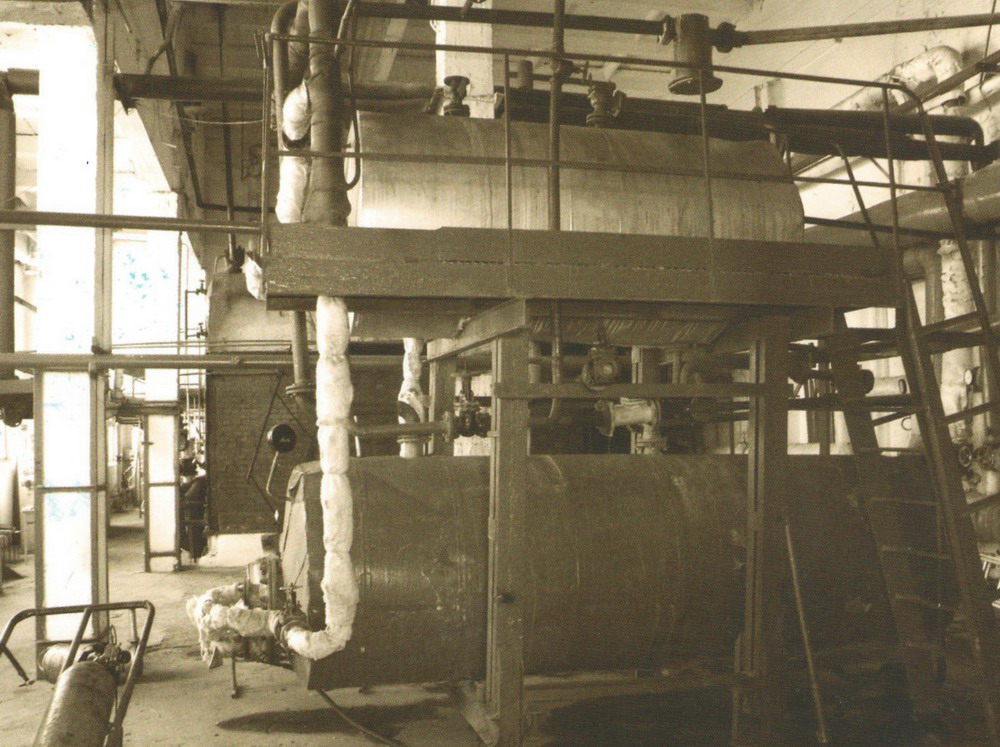

Designing a new plant

In 1964, Minsk Institute “Belprodrpoekt” began designing a new plant.

In May 1966, a new factory was built with a production capacity of 25 t per shift by milk processing. It was the head enterprise, which was in charge of Smorgon and Ostrovets Dairy Plants; in turn, the factory was included the regional association as a production unit.

In 1976, the factory became a production unit of the Grodno Regional Directorate for Dairy Products. In 1977, 119 employees worked at the factory. Sales volume of the released products amounted to 5,214 tons. The range of products included 18 various items.

New whole milk shop

In December 1991, a new whole milk shop was launched on the expanded site, and a new receipt and washing department was commissioned.

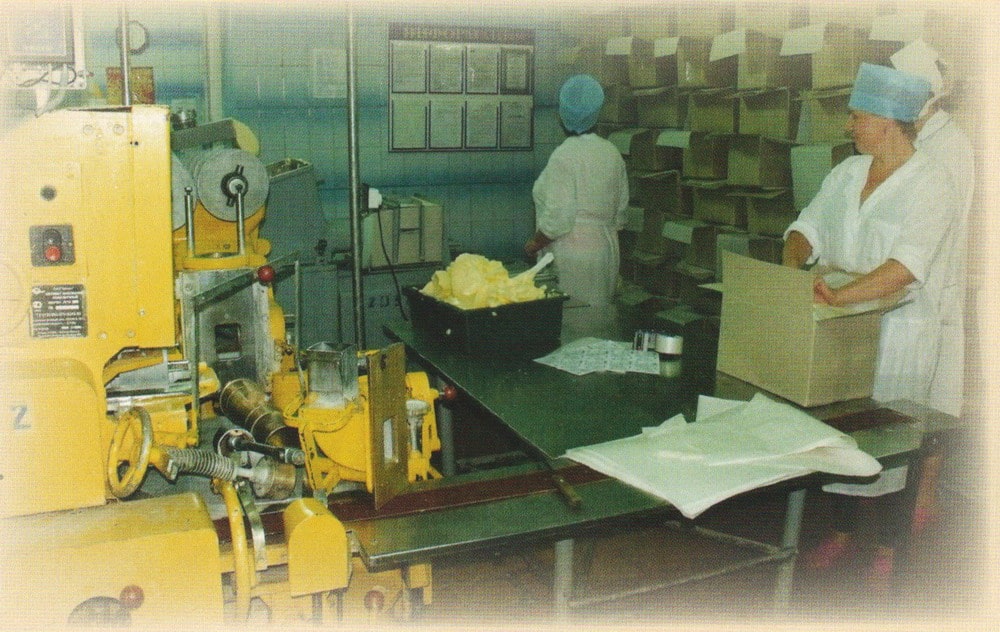

Melted cheese production shop

In 1998, melted cheese production shop was launched at the Oshmiany Cheese Works.

Modernization of the hard cheese production shop

The first start-up facility of the investment project “Modernization of the hard cheese production shop” was implemented.

In the course of implementation of the first start-up facility of the investment project, hard cheese production site was reconstructed. A new OBRAM line with a daily capacity of 10 tons was purchased for production of Russian and Dutch type cheeses.

Reconstruction of the butter production site

In December 2007, butter production site was reconstructed. An important strategic decision was made at the enterprise: to specialize in production of abomasal cheeses and butter instead of whole milk products.

Reconstruction of the cheese salting shop

In March 2009, reconstruction of the cheese salting shop of the “River” type was completed, as well as reconstruction of the compressor site. The section for production of butter using HFA method was also reconstructed.

Reconstruction of the whey separation shop

In 2011, reconstruction of the whey separation shop was performed. The line for whey condensing by NF/RO method manufactured by A-Lima-Bis was installed. Line capacity is 10,000 l per hour.

On December 29, 2011, Oshmiany Cheese Works JSC has been reorganized as a part of Lida Dairy and Packaged Food Works JSC; since then, the enterprise has been a branch of the Lida Dairy and Packaged Food Works JSC.

Implementation of the project “Modernization of the cheese making shop with an increase in production capacity to 20 tons of cheese per day”

Completion of implementation of the project “Modernization of the cheese making shop with an increase in production capacity to 20 tons of cheese per day”.

FIBOSA cheese production line was installed. Capacity of the line is 5 t per day.

Investment project “Modernization of the system of air conditioning and microclimate in the cheese making shop”

In the second quarter of 2016, investment project “Modernization of the system of air conditioning and microclimate in the cheese making shop” was implemented at the enterprise.

In December 2020, implementation of the investment project “Construction of cheese maturing chamber” was completed

The project resulted in construction of a huge building with an area of 3,308.1 square meters. It contains eight refrigerating chambers for cheese maturing with temperature mode from 8 to 12 degrees. Simultaneous maturing of up to 1099 tons of cheese can be performed in the chambers.